In-Mold Decorations in Modern Manufacturing: A Comprehensive Overview

In-Mold Decorations in Modern Manufacturing: A Comprehensive Overview

Blog Article

Mastering In-Mold Decorations: Methods, Trends, and Finest Practices for Optimum Outcomes

In the realm of production, the art of in-mold designs stands as a crucial facet of product design and manufacturing. In-Mold Decorations. By diving right into the strategies, patterns, and finest techniques that underpin successful in-mold design procedures, services can unlock a world of opportunities that not just boost the visual attraction of their items but additionally improve production performance and strengthen consumer engagement.

Material Choice

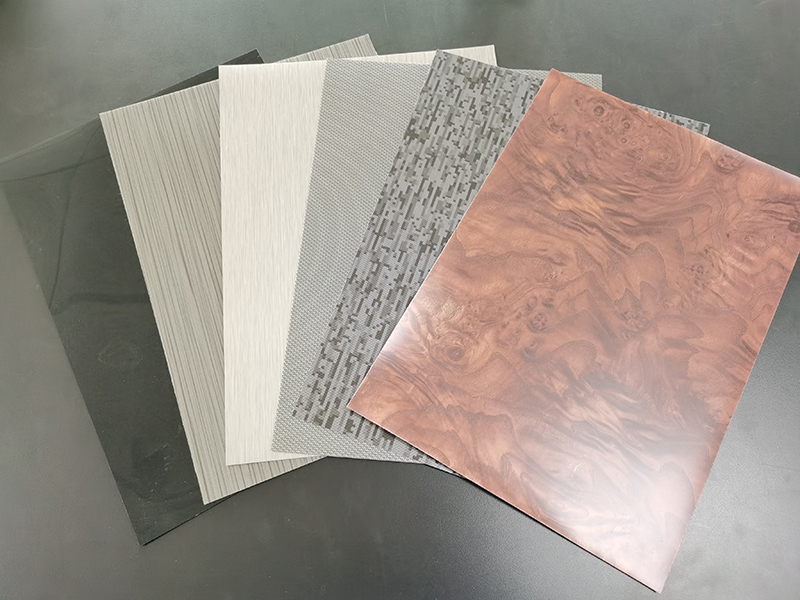

Material option is an essential aspect of grasping in-mold decors, as it directly influences the top quality and sturdiness of the final product. When selecting products for in-mold designs, it is crucial to take into consideration elements such as compatibility with the molding procedure, the preferred visual result, and the ecological conditions the product will deal with.

Additionally, products with high warm resistance are favored for in-mold decorations, particularly for items that will be exposed to elevated temperatures during their lifecycle. By very carefully picking the appropriate product for in-mold designs, suppliers can boost the overall high quality and longevity of their items, fulfilling the assumptions of both clients and end-users - In-Mold Decorations.

Style Innovation

A necessary element in advancing the area of in-mold decors is the constant exploration and application of layout technology techniques. Layout advancement plays an important function in enhancing the aesthetic allure, performance, and general high quality of items manufactured using in-mold decoration procedures. By integrating cutting-edge design aspects, makers can differentiate their items in the marketplace, bring in customers, and stay ahead of rivals.

Among the key facets of design technology in in-mold decors is the integration of complex patterns, appearances, and graphics that were previously challenging to accomplish with typical decoration techniques. Advanced technologies such as 3D printing and electronic design devices enable developers to produce complicated and in-depth layouts that can be flawlessly moved onto molded parts. In addition, making use of lively shades, metallic surfaces, and unique effects like gloss or matte structures can better elevate the visual allure of in-mold decorated items.

Furthermore, design technology expands past visual appeals to include functional improvements such as ergonomic forms, integrated features, and customizable elements that cater to certain individual needs. By embracing layout innovation, suppliers can unlock brand-new opportunities for imagination, item, and customization distinction in the affordable landscape of in-mold designs.

Manufacturing Effectiveness

Reliable production procedures are necessary for equating the cutting-edge designs created in the field of in-mold decorations right into high-grade finished items that fulfill market needs and consumer expectations. In the world of in-mold designs, production efficiency incorporates numerous crucial aspects that add to the overall success of the production procedure.

Automation not only accelerates the manufacturing process however likewise improves accuracy and repeatability, leading to a much more top quality and uniform end item. Overall, an all natural strategy to production performance is extremely important in maximizing the potential see post of in-mold decor methods and accomplishing optimal outcomes in the competitive market landscape.

Top Quality Control Measures

What are the vital approaches for making certain rigorous quality assurance actions in the world of in-mold decorations? Quality assurance procedures are vital in in-mold design processes to guarantee the manufacturing of top notch and perfect finished items. One vital strategy is the application of extensive assessment procedures at every phase of the manufacturing procedure. This involves carrying out detailed visual assessments, dimensional checks, and color uniformity analyses to determine any issues or incongruities early.

Using sophisticated innovations such as automatic assessment systems can likewise enhance the quality assurance procedure by giving dependable and exact information for evaluation. These systems can identify imperfections that might be missed by hand-operated examinations, therefore boosting overall item top quality and consistency.

Normal training and advancement programs for employees involved in the in-mold decor process can additionally add to keeping top notch criteria. By enlightening team on best techniques, high quality assumptions, and the importance of focus to detail, companies can cultivate a culture of quality awareness throughout the organization.

Consumer Charm

To enhance the bankability of in-mold design items, understanding and catering to customer choices play a crucial function in identifying their appeal and success. Customer charm in in-mold decors is influenced by numerous aspects, consisting of layout appearances, color selections, resilience, and general capability. Consumers are increasingly seeking individualized and unique items that mirror their uniqueness and design. Providing personalization options such as personalized designs, color variants, and textural components can dramatically enhance the charm of in-mold decor products.

Final Thought

In-mold decors supply a functional and effective means to boost item looks. Grasping in-mold designs requires an all natural method that takes into consideration all Discover More elements of the manufacturing process to ensure success.

In the world of manufacturing, the art of in-mold decorations stands as an essential element of product layout and manufacturing. Design technology plays a crucial duty in boosting the visual charm, functionality, and total high quality of items produced using in-mold decoration procedures.One of the crucial elements of design technology in in-mold designs is the integration of detailed patterns, structures, and graphics that were previously challenging to accomplish with typical decor approaches.Effective manufacturing processes are essential for translating the ingenious styles developed in the area of in-mold decors into high-quality completed items that satisfy market needs and consumer description expectations. Supplying customization choices such as personalized styles, shade variants, and textural aspects can significantly improve the allure of in-mold decoration products.

Report this page